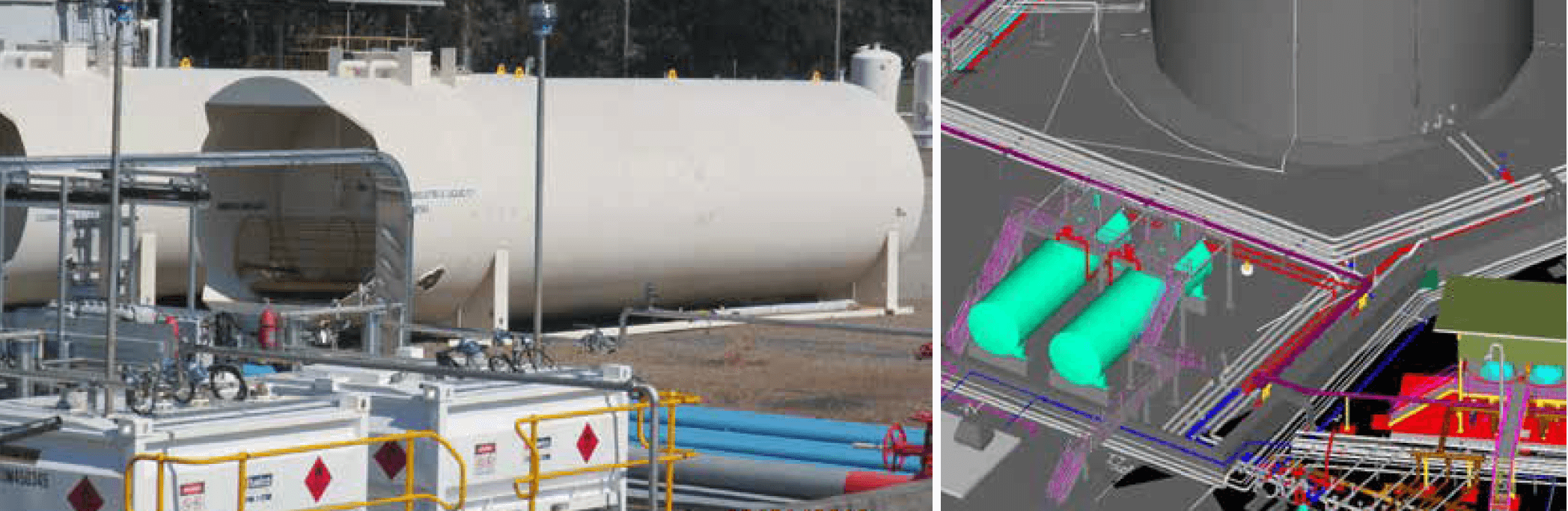

"We delivered an innovative solution to fast track the expansion of a fuel terminal to meet the growing market for high performance fuels. Our multidiscipline engineering team repurposed a number of tanks, including existing (mothballed) double-walled ethanol tanks, and supported integration of the additional storage capacity into a complex and challenging brownfield environment.

Geoffrey Constable

Projects Director

Detailed Design

Fuel Terminal

6 Months

TIC $1.9M

The project scope was modify two new ethanol storage tanks and two existing API 650 bulk storage tanks at the BP Newcastle Terminal to increase storage capacity for M98 fuel.

Process Consultants performed the process, civil, structural, mechanical, pipe stressing and fire safety design components.

Process Consultants provided an innovative solution for this project, utilising two previously mothballed double walled storage tanks to increase the M98 fuel capacity. As an initial project step it was necessary to complete a site visit to confirm dimensions of these tanks due to the lack of vendor data from their original build.

With the tank dimensional data confirmed we were able to complete the design of the new installation as planned, managing the technical complexities of issues such fire safety and pipe stressing, which required careful attention due the the layout constraints of the facility.

By working in closely with the client, understanding their requirements, and advising on potential options

where multiple solutions arose, we were able to deliver a successful project for them.

Process Consultants successfully supported the integration of the new storage unit into the existing facility, meeting project schedule requirements. Engineering services were tailored to meet the specific project requirements, with non-essential deliverables eliminated from scope. Process Consultants scoped and specified modifications to the double walled ethanol storage tanks, allowing them to fully utilise available working volume, whilst meeting AS1940 requirements.